Give your projects a unique opportunity: to benefit from the expertise of a vertically integrated partner with almost 100 years’ experience in all the stages of manufacturing and converting skin-compatible adhesives.

Every stage of the manufacturing process can be adapted to the constraints and requirements of your specifications:

-

1

Understanding the specifications

-

2

Selection of materials & Prototyping

-

3Formulation

-

4Coating

-

5Die-cutting

-

6Packaging

Our goal: to create THE medical device for your needs

Whether it’s customising each component of the dressing or simply its packaging, Laboratoires Coluxia can develop your project in a very short space of time. For more information, please contact us.

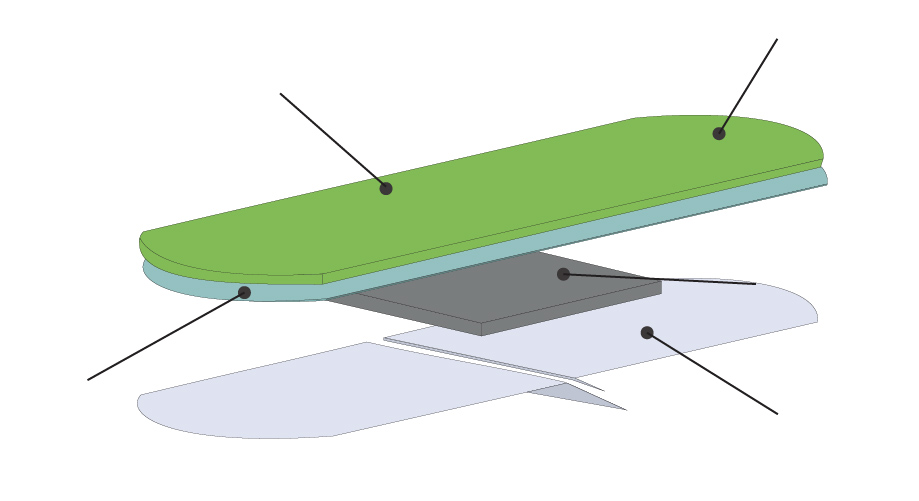

INTEGRAL TAILOR-MADE DEVELOPMENT

Laboratoires Coluxia manufacture your tailor-made medical device from A to Z.

Materials’ choice:

- Elastic

- Plastic

- Non-woven

- PU film

- Custom material

Cut’s choice:

- Straight edges/round edges

- Joint

- Cross

- Finger strip

- Jumbo

- Butterfly

- Roll

- Band

- Other tailor-made formats

Configuration:

- Island pad

- Plain pad

Type:

- Absorbent or super-absorbent

- Standard or antibacterial

- Custom material

Adhesive masses’ formulation:

- Solvent or emulsion acrylic adhesive

- Durastripe technology adhesive

- Silicone gel

- Adhesive with custom ingredients (essential oils, CBD, CMC, etc.)

Liner’s choice:

For a better cleanliness and easier opening

- Embossed PE plastic

- Siliconised paper

- Custom material

BRANDED PACKAGING

Do you want to stand out from your competitors while enhancing your brand? We can help!

Laboratoires Coluxia can customize all types of packaging in a highly flexible way, transforming your packaging into a true showcase for your brand. Get in touch with us!